Artificial intelligence is being implemented within nearly every aspect of our lives and is slowly changing the face of manufacturing. We only need to look at Industry 4.0 to see its vital part within a manufacturer’s roadmap. Technological advancement is a prime candidate to optimise manufacturing processes, automate complex tasks and identify unknown patterns in workflows.

The manufacturing industry is leveraging this game-changing technology with a 60% adoption rate in 2020 (using in at least one business function). This means manufacturers are starting to realise the huge potential of utilising AI to increase their commercial advantage.

What is Holding Manufacturers Back?

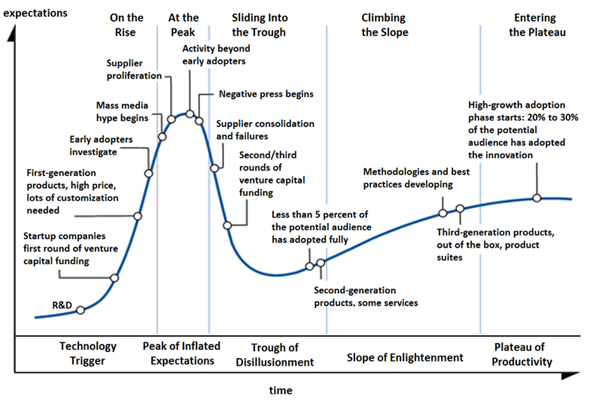

AI is revolutionising almost all sectors, giving empowerment to companies across the globe to gain immense value from their data. Utilising AI can help manufacturers increase operational efficiency, reduce downtime, and deliver high-quality products. If this sophisticated technology is the epitome of Industry 4.0, why is the install rate relatively small?

Outdated Technological Infrastructure

Manufacturers often use a wide variety of machines, tools and systems that use different and competing technologies. Some of these may be outdated and not compatible with their other technological infrastructure. This combined with a lack of digitalisation is preventing manufacturers from capitalising on the potential.

Confidence, Uncertainty and Trust

A significant barrier to AI adoption is the trust and confidence in the capabilities of abstract algorithms. Personnel within manufacturing who don’t hold a data science background struggle to validate how predictive modelling and data science work together.

JetSoft’s Use of AI in Manufacturing

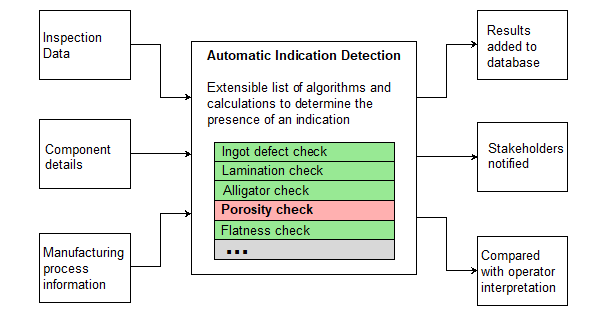

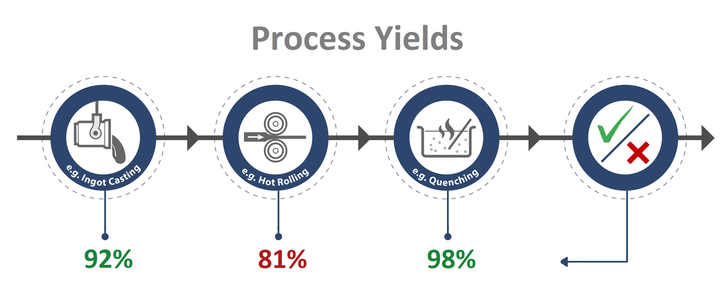

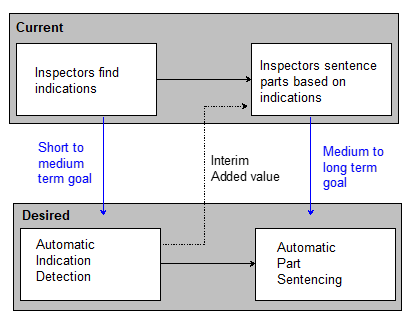

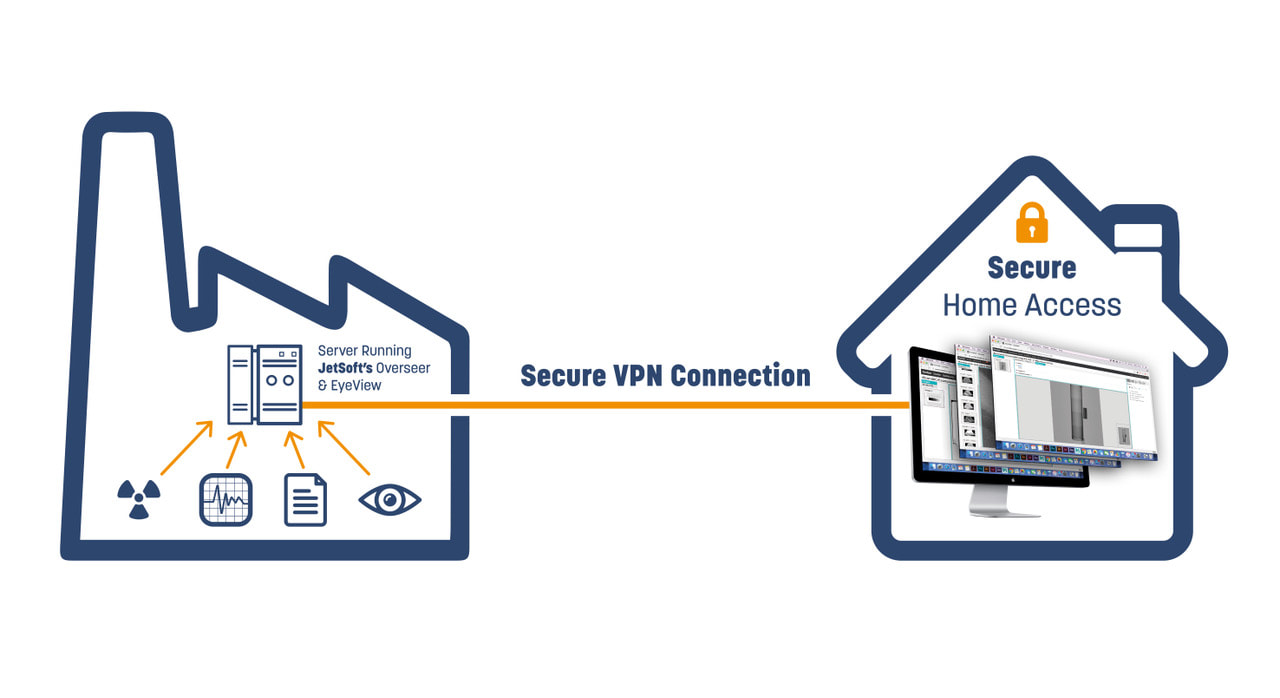

JetSoft employs AI techniques to automatically analyse inspection and manufacturing data, to detect anomalies in product output and associate them with the upstream processes that created them. Manufacturers gain deep insights to understand the correlations in inspection failures and deploy targeted process improvements, to reduce the likelihood of that anomaly occurring again.

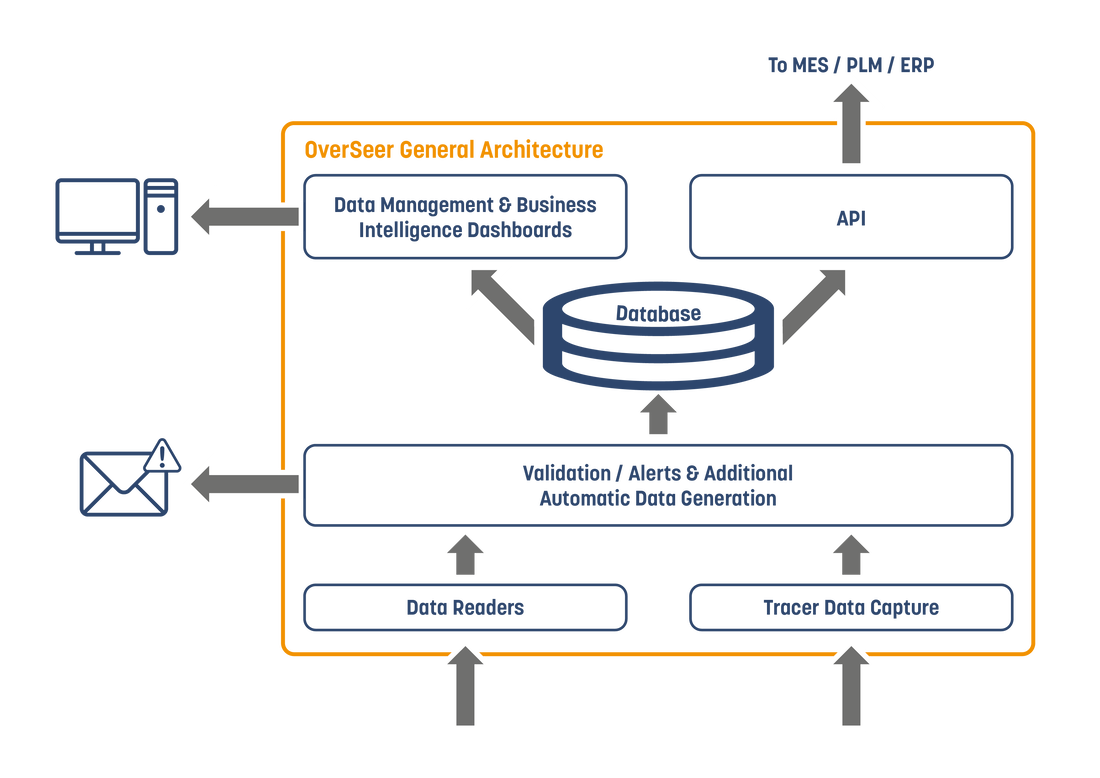

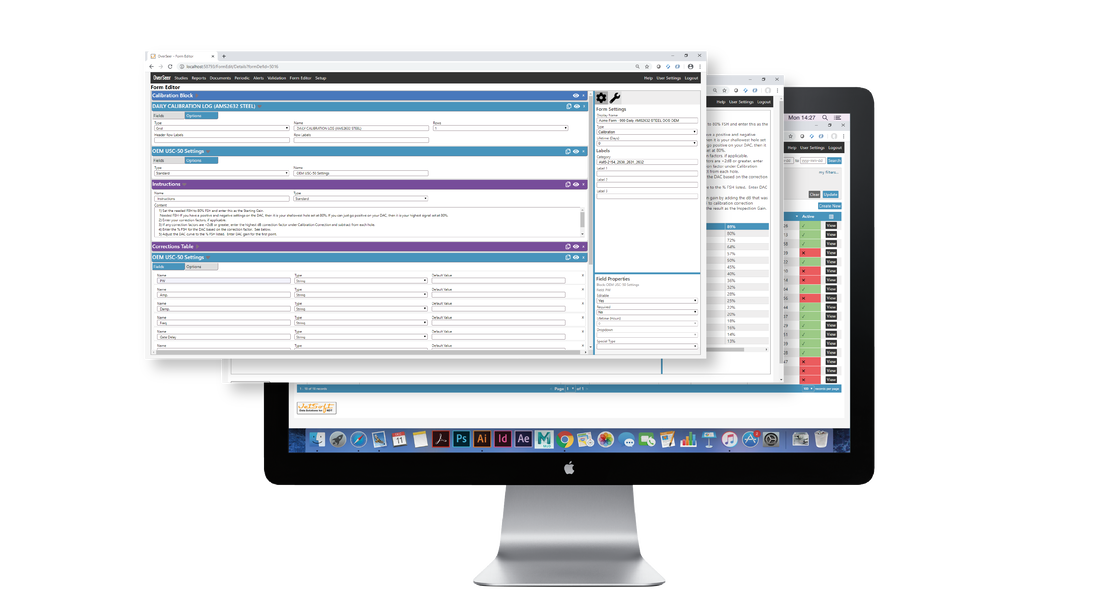

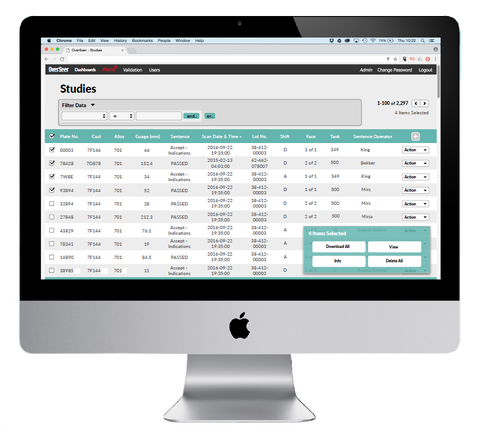

Our OverSeer solution automatically manages inspection data and techniques from different sources. OverSeer reads and places the data automatically into a central database to perform thorough assessments. Data from new inspections can be tracked as it passes through each module that has an output. Working on legacy formats means our cutting-edge AI technology is able to analyse historic data from manufacturers to instantly spot anomalies and defects.

JetSoft deploys AI technology into a customer's site, which analyses images and inspection data to automatically detect anomalies and patterns within the data. The AI functionality pinpoints which processes have created the specific anomaly without having to stop the entire production to detect and fix the problem. Manufacturing personnel are then able to analyse the anomaly against a defect specification to gain a deeper insight into if the anomaly has become a defect.

Benefits of AI in Manufacturing

The applications of using AI are widespread and revolutionising, offering actionable insights into reducing waste and scrap. So, what are the overall benefits of using AI in manufacturing?

Predictive Analytics for Increased Production Output

AI systems are able to learn from machine learning algorithms and make use of predictive analytics. The manufacturing industry holds a large volume of data, which predictive analytics is powered from. Manufacturers can easily pinpoint anomalies without disrupting the production process.

Improved Process Quality

AI technology creates an efficient production process, resulting in higher product quality. The software ensures that products going through the inspection stage don’t just meet quality standards but are of higher quality and closer to nominal.

Reduction of Scrap and Waste

Early detection of anomalies using AI techniques allows manufacturers to make quick industry-related decisions that won’t further impact production and create more waste. Reducing waste and scrap has a direct correlation with profit generation and the bottom line. When high-quality products are always created, manufacturers are maximising their output without having to scrap any materials. Utilising assets more effectively creates a reduction in the variable cost of each component, meaning lower prices can be introduced to become more competitive. Minimising component costs ultimately creates a more profitable company.

Implementing our solutions has allowed established clients to benefit from huge commercial gains. One JetSoft customer who using our solutions has reduced their scrap rates by over 60%, resulting in savings in excess of $2m a year.

AI solutions allow manufacturers to utilise their assets more effectively and take advantage of commercial gains. If you want to know more about how JetSoft can help you, get in touch.