Tracer

Data capture for manual manufacturing processes.

Existing data-capture practices often rely on operators’ notes, stored in disparate spreadsheets or even paper records. This makes data difficult to access and compile, and detailed analysis is impractical at best.

With Tracer, capturing uniform, accessible data is simple. An intuitive user interface provides simple tools to accurately record data on a 3D model, with automated report generation.

As part of the OverSeer framework, data is stored centrally, enabling further analysis to identify trends and insight, driving continuous improvement and increased productivity.

Existing data-capture practices often rely on operators’ notes, stored in disparate spreadsheets or even paper records. This makes data difficult to access and compile, and detailed analysis is impractical at best.

With Tracer, capturing uniform, accessible data is simple. An intuitive user interface provides simple tools to accurately record data on a 3D model, with automated report generation.

As part of the OverSeer framework, data is stored centrally, enabling further analysis to identify trends and insight, driving continuous improvement and increased productivity.

|

Benefits and features

|

|

|

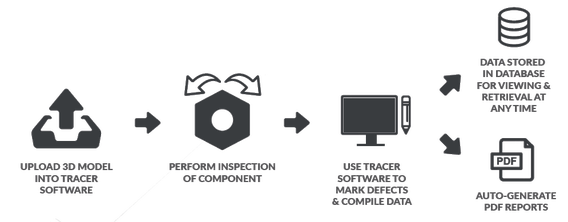

How it works

- Users perform an inspection

- Via their computer terminal they log on the system and enter information about the inspection

- Drawing regions of interest onto a 3D model and uploading any additional files (e.g. digital photographs)

- They press a button to automatically create a PDF report and upload all the data into OverSeer

- Data is traceable and easy to find, and can be compiled to enable trend analysis and the creation of defect heatmaps

Product Downloads

| tracer_datasheet.pdf | |

| File Size: | 4452 kb |

| File Type: | |

Related Products

|

OverSeer

Allows NDT information to be catalogued and easily searched. Business intelligent functions provide a clearer view of NDT processes Read More |

EyeView

Our zero install image viewing and analysis tool. EyeView allows remote evaluation and improved accessibility to NDT information Read More |