Helping Out Hansen Aerospace

Client: Hansen Aerospace

One of our ultrasonic testing (UT) equipment manufacturing partners came to us not long ago with a customer who was looking for assistance. They were looking for a solution to aid them in managing their large data volumes, and the large regulatory overhead that comes from working across the primes. They were also looking to have a more detailed understanding of the operations to improve their value proposition to their clients.

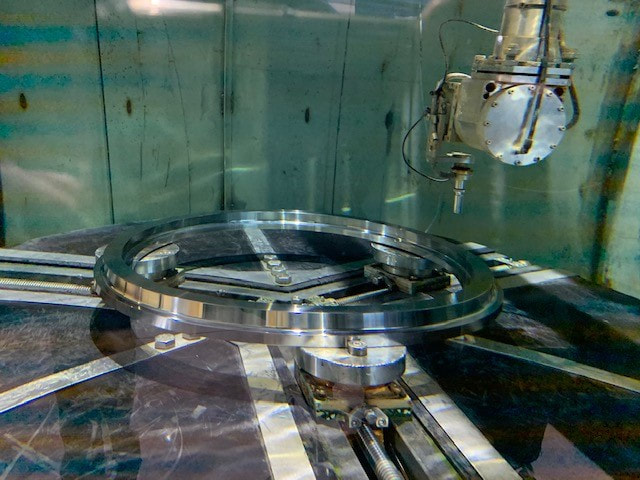

Hansen are a world leading company in NDT inspection and coatings based near Boston MA USA. Having been in the business for 35+ years, they deliver high-quality, non-destructive testing services within multiple markets, including aerospace, power generation, medical, nuclear and automotive. Their largest department is their ultrasonic testing department which includes more than 30 digital C-scan inspection systems.

The Aim

In recent years Hansen have been experiencing the rapid growth that comes with delivering a sector recognised quality service.

This expansion, as often happens comes with growing pains associated around efficiency and management. Hansen wanted to invest in systems to aid this growth while maximising the opportunity to improve customer satisfaction levels. Working with many of the aerospace primes means that Hansen has many individual requirements to meet for inspection processes, and they needed an improve upon system to manage this overhead.

Tailored Software

Hansen felt as though JetSoft had the most flexible data management solutions in the market and after our initial consultations with them, it was decided that the best option for them would be a combination of OverSeer, EyeView and DigiOps would be the best solution for their specific needs.

What followed was a multi-step implementation process:

- First, we undertook key meetings to understand the functional requirements of the system, taking these requirements we developed a release plan.

- The initial release was done on site over a 2-week, period, working with Hansen engineers to test the release and taking feedback to identify where the system could be improved.

- Improvements were then iteratively developed and released remotely.

Overcoming Challenges

As with most software installs, this one didn’t come without its challenges. First of all, the huge volume of data that needed managing by Hansen was the highest volume of data we had tackled at this point in time, and we needed to do so without effecting the operation performance of the software.

We needed to ensure the software could read the machine output in near real time so that inspectors were able to add additional data to the inspection via OverSeer. For this to work with the installation we had to take the output data from the machines, read it into the database and make it searchable, and doing this almost instantaneously was one of the challenges of this particular project and an achievement we were particularly proud of.

Finally, we had to ensure that we could compile information that would provide key insights into the operations that would drive continuous improvement, fast issue resolutions and ultimately provide the greatest return on assets.

The Final Result

Hansen were extremely happy with the overall solution provided. They have been able to manage their C-Scans much more efficiently since the install and has even helped overcome some additional issues Hansen were not previously aware of. We were able to provide a smooth installation process and overcome challenges along the way to provide a full-service solution for our customer.

“We are extremely happy with the overall solution. I would highly recommend JetSoft for your NDT data management needs.” – Rob McGrath Hansen ASNT L3