Industry 4.0 is transforming the manufacturing industry. Manufacturers across the globe are digitally transforming their operations to leverage new capabilities, reduce costs, meet net-zero targets, and inform decision-making. Ultimately smart manufacturing creates new and improved ways of manufacturing.

Digital Thread

The term “digital thread” might seem to be a relatively new concept in manufacturing; however, it has been used for some time. The digital thread is defined as a communication network that closes the loop between the digital and physical world, by creating digital twins from their physical counterparts. The digital twin of a unique asset is connected to form the digital thread, showing a time lapse story of each asset and their digital twin. The digital thread is about getting the correct information from the plant floor, organising it all, and ensuring the right people see it in real-time. Afterall, NDE 4.0 is all about revolutionising inspection and maintenance processes to increase reliability, safety, and the economics of an asset. The process of a digital thread is formed throughout each stage of a product lifecycle such as:

- Idea generation

- Design

- Production of raw materials

- Manufactured components

- Product assembly

- Inspections

- End of life – Dissembled product or recycled

During each of these stages, a digital twin is captured to form a digital thread. During the lifetime of a product, a digital twin may be produced from different departments, suppliers, and companies.

Digitisation

The digital thread concept is therefore integral to digitisation. which is key to driving an efficient production line and creating traceability of all information produced from manufacturing operations. In manufacturing and NDE processes, huge amounts of data are produced and analysed to uncover insights into production line efficiency and asset performance. The digital thread captures and documents everything digitally, instead of through paper processes. Digitising traceable data is an effective way to analyse operations and inspections, track manufacturing history, and identify defects.

Advantages of Digital Thread

Applying the digital thread throughout manufacturing comes with a series of benefits:

- Improve product quality by limiting mistakes of manual input of data.

- Improve communication to make informed decisions.

- Increase the efficiency of digitally capturing and analyse data related to product manufacturing.

- Improve inspection equipment.

- Optimise maintenance plans such as identifying equipment that needs to be replaced.

LNS Research states that the digital thread can increase supply chain efficiency by 16%.

Digital Weave

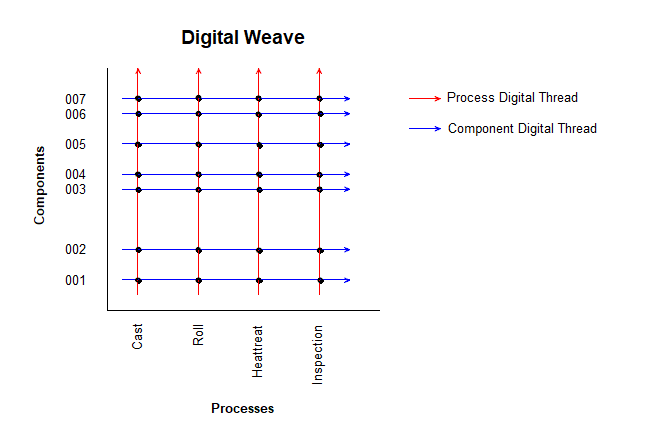

The digital thread weaves through the many facets of manufacturing operations. For example, each component thread weaves through a manufacturing process thread throughout different points of its lifecycle. Examples of these include various equipment and inspections. Assets and the manufacturing process threads weave together to create a digital weave, as shown in Figure 1.

Digital Weave in Action

JetSoft produces software which helps companies to understand how their process affects quality and yield. Jetsoft’s Overseer solution pinpoints the processes and cause of waste.

For example, we were able to diagnose that potential scrap inducing issues were being introduced by a process. This wasn’t due to the parameters of that process but due to what the system had been producing beforehand.

Let us explain

The process we analysed was material rolling, where the temperature of the rolls heats up during the manufacturing process. The amount of heat and thermal mass introduced is dependent on the product that is being produced. A heavily rolled material will introduce a lot of heat into the system. If enough time is not given for the system to return to ambient, then this will influence and potentially cause a defect to the next material that is due to be rolled. By analysing the manufacturing and inspection data we were able to identify and quantify this effect, which provided a much greater understanding of how processes, and affects quality.

JetSoft can help you produce an efficient production line, by digitising your inspection processes. Get in touch to find out more.