The impact of the energy crisis has dominated the news over the past few months. A sharp rise in global energy demand, a weakness in supply, and a change in the energy model has led to an energy shock. The price of fuel, transport and materials are putting pressure on production prices and forcing manufacturers to adjust.

The Energy Crisis

The manufacturing and industrial sector accounted for 16% of the total consumption of energy in 2019. Consuming 2,615 ktoe, placed them as the 4th highest business energy consumer. Energy usage is predominantly used to fuel the production line; however, the intensive use of energy has exposed the industry to the energy crisis.

Improving the Production Line

Whilst some costs for manufacturers are abating, unsustainable high energy market prices continue to be a key concern. As the industry is under extreme pressure, improving your operations performance should be of paramount importance. Due to the increased cost of energy inefficiencies in your production line are becoming more and more costly, and could be causing your business major commercial losses.

Defects in Manufacturing

Times of crisis and turmoil also create opportunity, ultimately, it is likely that we will see the inefficient business go out of business and the efficient ones become stronger and grow their market share. The key to this efficiency is the reduction of both time and material waste. Defect data and inspection information is integral to finding the inefficiencies in your production line and that’s where JetSoft can help.

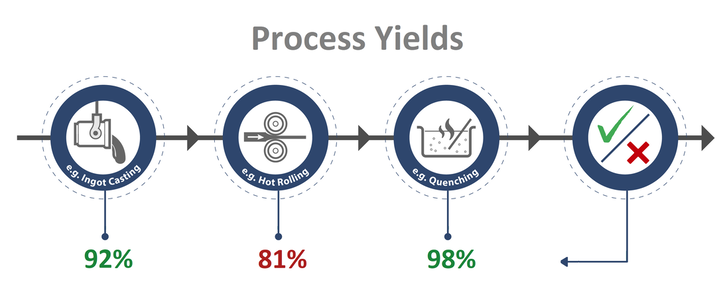

In manufacturing, defects can occur at any point however may may only be detected during the final stages of production at the testing phase. Time, money and energy may have been put into products that were always destined for the scrap bin because of an earlier defective stage. Products that are found to be defective either, have costly re-work or are scrapped. The duplication of manufacturing and the process of dealing with the flawed product causes an often-unnecessary increase in energy consumption that could have been avoidable in the first place.

Gaining Visibility

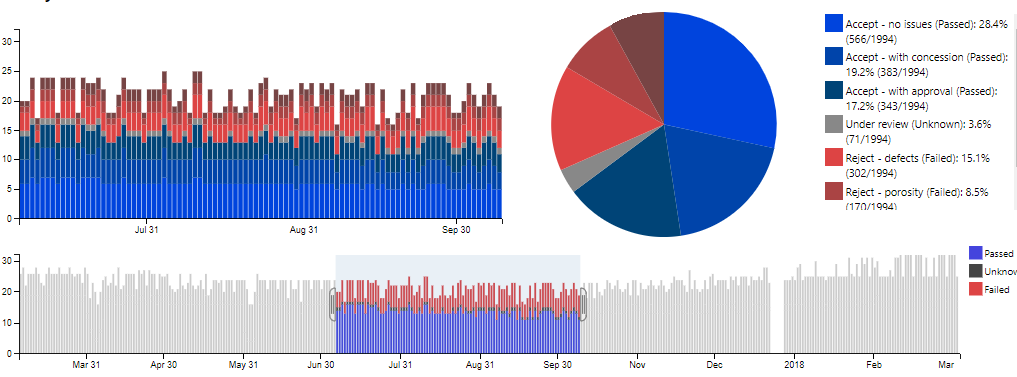

Greater visibility is key to addressing these immediate and long-term challenges. Leveraging technology can give manufacturers in-depth visibility of their assets, to manage the bottom line of energy usage costs. A deeper analysis of production lines is vital to understanding where the weaknesses lie. Having access to large quantities of NDT and inspection data that can be analysed can help manufacturers quickly identify and rectify the causes of defects.

Reducing Energy Consumption with JetSoft’s Solutions

JetSoft’s solutions aid manufacturers in increasing product quality and energy efficiency, by harnessing the value of their quality control data. OverSeer enables manufacturers to gain clear and in-depth insights into their NDT processes and production line. Quickly displaying live information that includes your product stream yield and machine utilisation rates, allows users to gain complete control of their NDT data and mitigate production loops.

Integrating integral data types is critical to enhancing predictive decision-making and driving intelligent change. Our OverSeer and DigiOps solutions capture and aggregate the complexities of inspection data, from a simple pass or fail to the most complex 3D imagery into the OverSeer platform. Our machine-learning algorithms can detect anomalies within your production line that may be costing you time and money.

Reduce Production Costs

JetSoft can help you highlight processes that are impacting excessive energy consumption so that you can increase productivity, improve commercial performance and in turn reduce your energy costs.

For example: JetSoft’s solutions may find that components passing through one particular machine are failing their NDT inspections more frequently, but the same component is passing if travelling through another production machine. This would indicate that there is a problem with the machinery rather than a design flaw. This constant analysis of your manufacturing data intertwined with inspection data, means our solution constantly detects the root cause of problems in manufacturing processes to avoid waste and extra time and energy spent remaking components.

Data-driven tools such as JetSoft’s solutions offer manufacturers a method to identify defects and weather the energy crisis storm. If you are looking to mitigate the energy crisis obstacles with visibility and resilience, get in touch.