JetSoft is delighted to announce that Sam Cunningham joins us today as our new Head of Sales and Marketing.

Sam is well known in the British NDT community, and has a broad range of experience in the industry, which includes being Non Executive Director of the British Institute of Non Destructive Testing (BINDT).

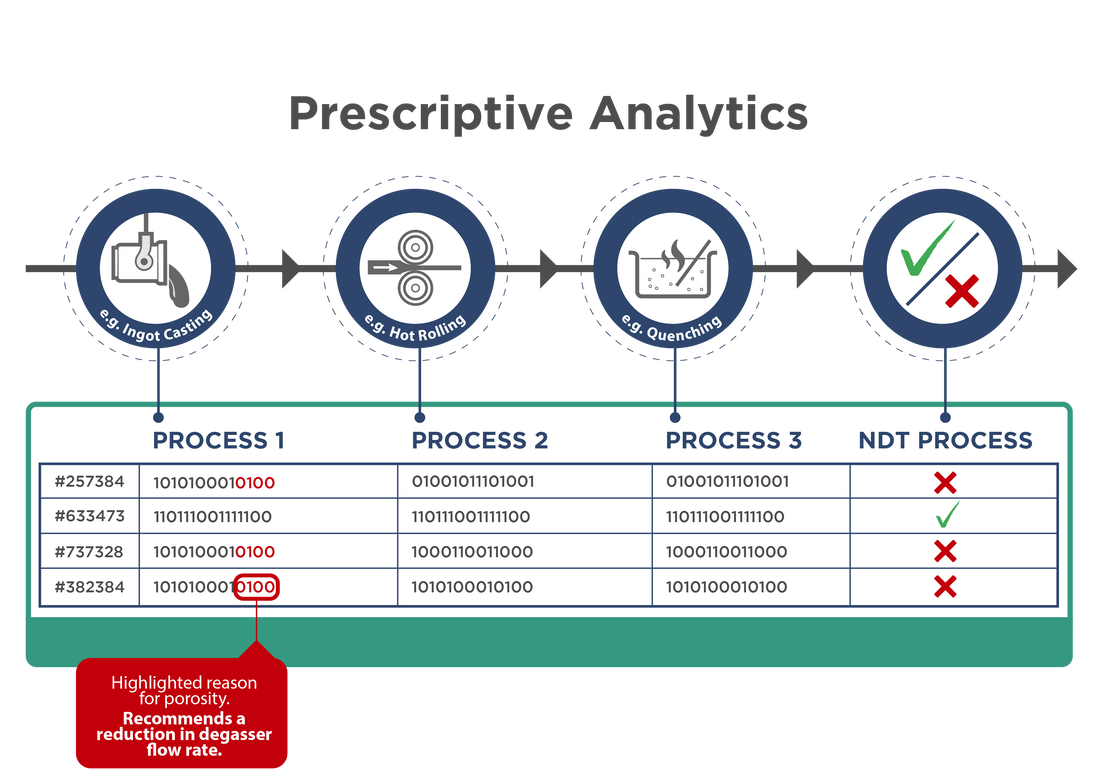

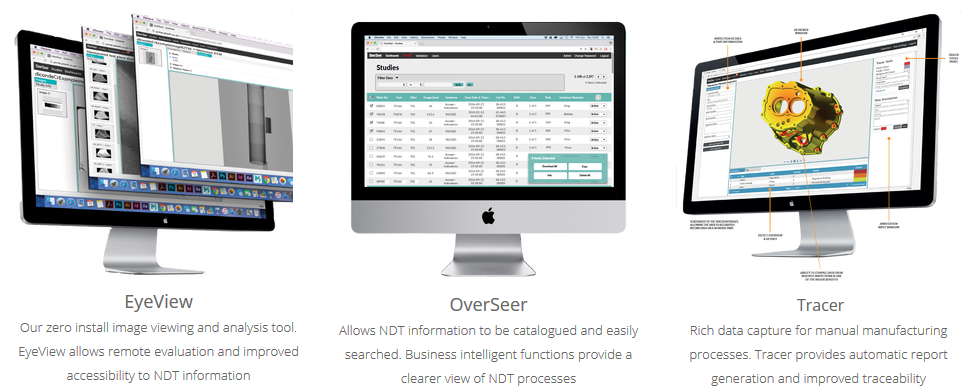

JetSoft is committed to making high quality appointments as we look to build a world class team, and Sam’s experience, aptitude and communication skills make him the perfect fit. JetSoft is approaching an exciting period, and Sam will be key to ensuring we realise our growth strategy and capitalise on our industry leading, game changing products.

“I have known Sam for a while, and I have always thought that he would make a great addition to the JetSoft team. I was ecstatic to get a positive reaction from Sam when we were able to present him with this exciting opportunity. We have an amazing array of innovative and revolutionary products that are already delivering significant commercial benefit to our clients, and with Sam’s help we can expand our offer and reach. All of us at JetSoft are thrilled to welcome Sam into the team. ”

Tom Martin, CEO

Please drop him a call or email to say hi, or to get a rundown on how JetSoft can help you!

[email protected]

+44 (0) 113 4931007