JetSoft is pleased to announce the delivery of OverSeer and EyeView to one of the world’s largest aluminium manufacturers.

OverSeer automatically reads and databases their inspection data. Operating across multiple techniques including Ultrasound and Conductivity and integrating to their Electronic Daily Management (EDM) system. OverSeer reads both new inspection data in real time as well as archiving their existing data collection with no down time to production. The scalable system currently holds over 65000 inspection records, with no effect on speed or usability.

This vast database of inspection data has quickly enabled JetSoft to provide some unique insights. For example, the dashboard visualisation that collected defect information across years’ worth of inspections in seconds, and depicts a 3D heatmap of defect locations, provided intriguing and surprising results, sparking a big debate within the office.

OverSeer’s unique and highly configurable dashboards allow users to isolate data on any criteria, so users can look at these statistics for individual alloys, furnaces or defect types.

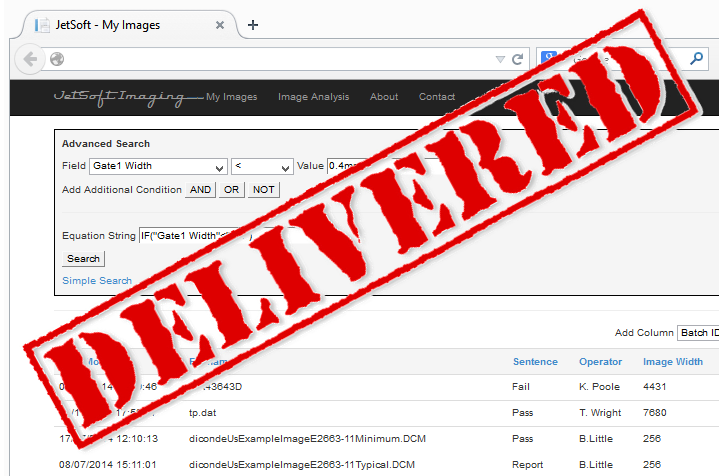

Meanwhile EyeView is facilitating the viewing and analysis of inspection data. This is administered straight from the server using a web browser, for zero-install and remote access, instantly allowing access (via VPN) from home or different sites.

A key feature that has been developed in conjunction with the customer is our new validation module. This enables rules to be set up, notifying the user in real time should certain criteria be met. Examples include: alerting if a reference panel scan doesn’t occur within a specified period, if operators are not following the correct procedures, or if a part is scanned that contains a certain defect. Previously, these checks were undertaken manually, and consequently a big time efficiency has been realised.

Conversations are happening with the client regarding piloting JetSoft’s new machine learning module that integrates in other process data, drastically reducing scrap rates. More information on this to come.

To say the customer is happy is an understatement, and we are currently in discussions about rolling out JetSoft solutions across other sites.

JetSoft is a software company that specialise in NDT data, with an aim to improve the accessibility and efficiency of this under-valued resource, that has the potential to revolutionise manufacturing.

We welcome questions and comments, and please get in touch to see how we could help you.