Picture Archiving and Communication Systems (PACS) provide central storage and access to images from multiple sources across multiple techniques. The Picture in the PACS acronym is a bit of a misnomer as PACS don’t just deal in pictures. They also contain all the data around that picture, including when/by who/how that picture was taken. It contains that critical, contextual information that is written on the back of an old photograph.

Where are they used?

PACS are used extensively and ubiquitously in the medical world, enabling a plethora of medical practitioners to offer a smooth patient centric service. PACS act as a hub in the network of collection equipment and viewing terminals, allowing the collectors of data and the evaluators to work at arms length. Medical images can be transferred electronically and so instantaneously to wherever the patient requires them. Medical PACS revolve around the DICOM standard, and are very mature, having been first developed in the 1970s.

What are the benefits?

This is great for the medical industry, but why do we need them for industrial NDT? Well, we do but for different reasons, reasons that are becoming more critical and useful.

Unlike the medical industry manufacturing is production, not component centric. In the DICONDE format – the NDT equivalent of DICOM standard – component is analogous for patient, except the component is not normally a repeat customer and the suite of tests in manufacturing are generally prescribed and linear, and diagnosis is normally subject to quantifiable standards.

However, industry can benefit from PACS technology in other ways. As projects become more global (such the countries participating in the F35 project), and companies become more likely to have an off site level 3, stakeholders or critical NDT decision makers are not in the same location as the inspection. In this case a PACS helps to make the flow of data and communication more efficient, reducing the time needed to make a decision thus making manufacturing more efficient.

NDT image data quantity is expanding and becoming more complex, both in terms of volume and size, and quite often management of that data will incorrectly fall on to the NDT department. They have the impossible task of managing continuous data generation across many different proprietary formats from multiple locations and techniques. A good PACS will order this data automatically, make this data manageable, and provide quick and easy search and view functions, reducing the time demands on key NDT personnel allowing them to work more effectively.

Where can I get one?

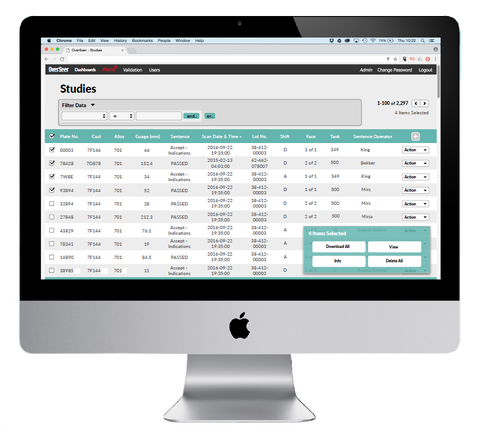

JetSoft’s OverSeer is a PACS solution that specialises in NDT information. OverSeer can automatically read and understand many different formats from multiple suppliers and techniques, reducing resources absorbed with data management. OverSeer is DICONDE compliant and so can both input and output DICONDE information and can act as a DICONDE converter for your existing data.

OverSeer’s database with web interface makes it easy to search and find inspections by their contextual information, for example all the scans done on a particular piece of equipment, by a certain operator or with a particular defect.

OverSeer goes further than a standard PACS and offers Business Intelligence functionality, allowing performance of Statistical Process Control (SPC), trend analysis, and full health check of the NDT department.

By using OverSeer and having NDT information in a central database allows us to perform some new types of analysis, including data fusion, automatic defect recognition, or dataset analysis. An example of this was a defect heatmap that was recently performed for a JetSoft customer, which provided new insight and enlightening results

For more information or to arrange a demonstration please get in contact with JetSoft.

http://www.jetsoft.co.uk/contact.html