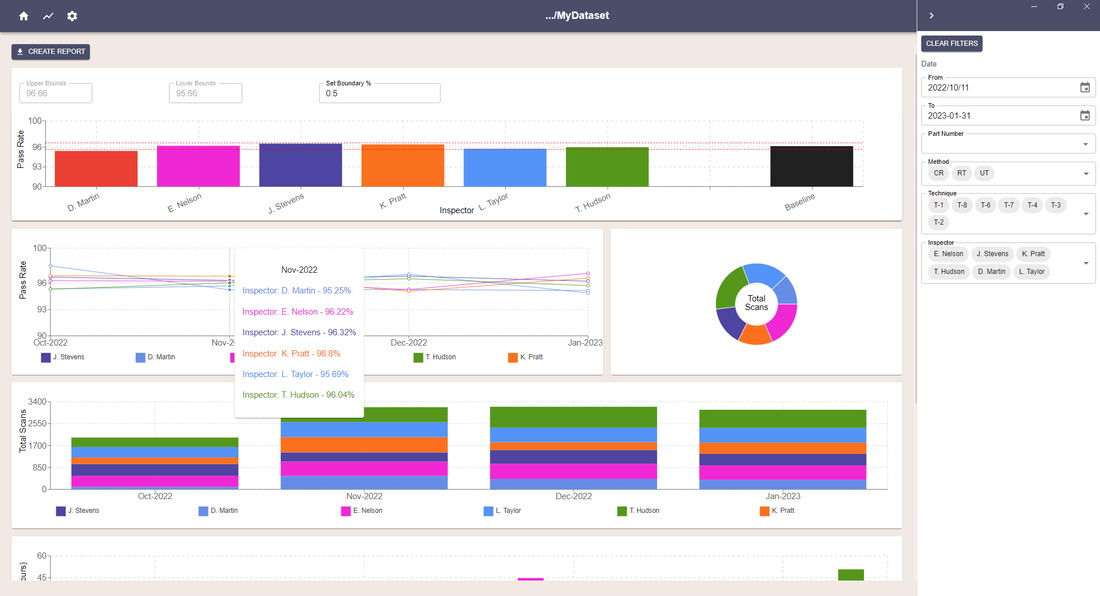

| We have recently heard a lot about the revised NADCAP (National Aerospace and Defence Contractors Accreditation Program) regulations which mean companies must now monitor defect rates across inspectors, part types, and methods. The revisions apply specifically to AC7114 Rev R, an audit criterion used to assess companies that are performing non-destructive testing. As much of the industry continues to make adjustments to their processes in order to meet these new regulations, we caught up with our Founder and CEO, Tom Martin on how he thinks these new regulations will affect manufacturers and how JetSoft’s latest development, Inspection Results Monitor, is here to help. |

Can you give us a full run through on exactly what changes have been made to the NADCAP regulations?

A significant change has been added to the NADCAP checklist that requires certain NADCAP approved companies which perform inspection processes to gather statistics on inspector pass rates.

Why are these regulation changes so important within the industry?

Actually, these new regulations are quite controversial. And I’m not sure I entirely agree with them. They’re there to detect anomalies in testing results generated by human factors. Unfortunately, often other factors will mask these, especially in low production environments. A change in upstream manufacturing processes can have a huge effect on quality and defect rates, we see this everyday at JetSoft. In this case the change in defect rate, which is nothing to do the inspector, will skew the results of this assessment. Even worse, should the inspectors have knowledge of these rates it could add another bias into the inspection process. However, human factors are a cause for concern, and it’s right that methods should be put in place to prevent them from influencing defect detection.

How are these changes likely to affect manufacturers?

It adds another requirement to inspection department managers, which most aren’t currently equipped to deal with. Cue hastily designed spreadsheets and yet another overhead requirement. And remember you can’t ask operators to complete this as they should be concealed from the results, to prevent bias, so the responsibility completely falls on the inspection department manager.

What can be done to lessen the impact on manufacturers?

Get Inspection Results Monitor! If you’re reading this and have gotten this far, download it and give it a go. If you don’t like it or you find that it doesn’t meet your needs, get in contact with us and we can see how we can adapt the software to meet your specific needs.

Why did you choose to develop IRM?

JetSoft is all about creating software solutions to help with the management and utilisation of inspection data. This is what we do, therefore, we felt we were in an ideal place to develop a solution to help companies meet this newly revised NADCAP AC7114 Rev R regulation. And I must say we are very proud of the result; Inspection Results Monitor is a lightweight application that is designed to meet these new regulations as easily and simply as possible.

Any other thoughts on this area?

Interestingly these requirements are not applied to automated indication evaluation. There is potential, especially if the requirements get more onerous, that this could this be a driver for automated analysis. However, I suspect this won’t be the case unless the requirements drastically increase.

If you are looking for a digitised solution to meet and adhere to the NADCAP regulations and requirements, look no further. Get in touch with a member of our team to find out how Inspection Results Monitor can benefit you.