JetSoft is pleased to announce the delivery of a bespoke software application to a leading Dutch aerospace company.

The >100 year old company had identified a risk with inspection data that left them relying on discontinued, unsupported software. The DOS operated, legacy, automated ultrasonic equipment was supplied by a now defunct company, but operated and inspected components efficiently. However, the vast data collected over the lifetime of the machine was only viewable on the scanner itself.

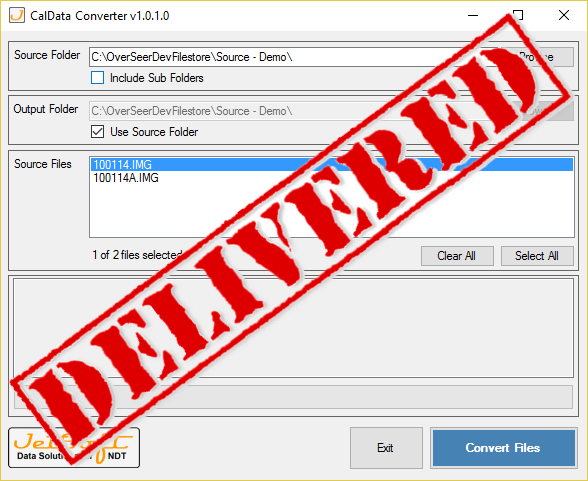

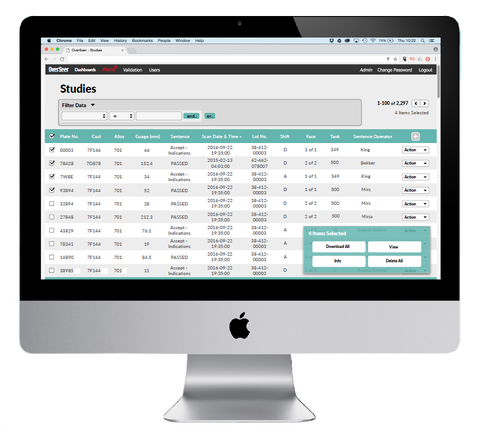

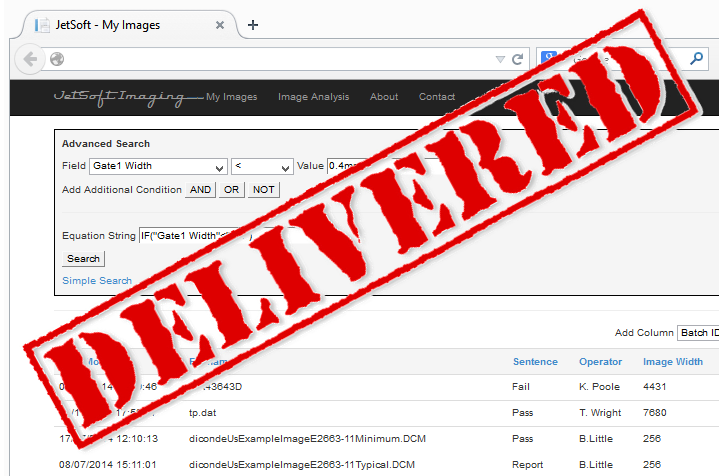

There is a regulatory requirement that the inspection data should be viewable at any time, during the life of the aircraft. JetSoft was able to harness its unique skillsets in software, data formats and NDT to reverse engineer the inspection data files and convert them to a standard format. The bespoke application is simple to use and dynamically converts files, which can then be viewed and read on other operational equipment. This removed the risk and extended the operating life of the machine.

JetSoft is a software company that specialises in NDT data, with an aim to improve the accessibility and efficiency of this undervalued resource that has the potential to revolutionise manufacturing.

We welcome questions and comments, and please get in touch to see how we could help you.