OverSeer in Action

We are working on one of our most exciting projects to date, this project for a major UK aerospace company, pushing our OverSeer solution further than ever before.

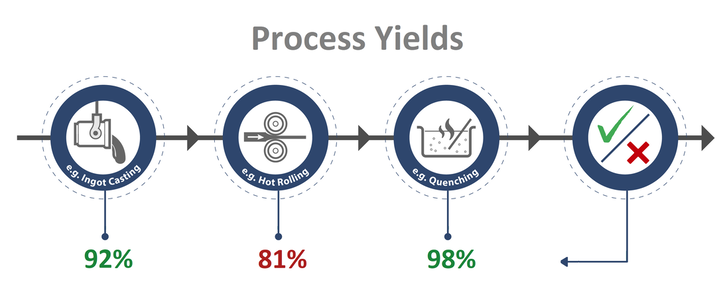

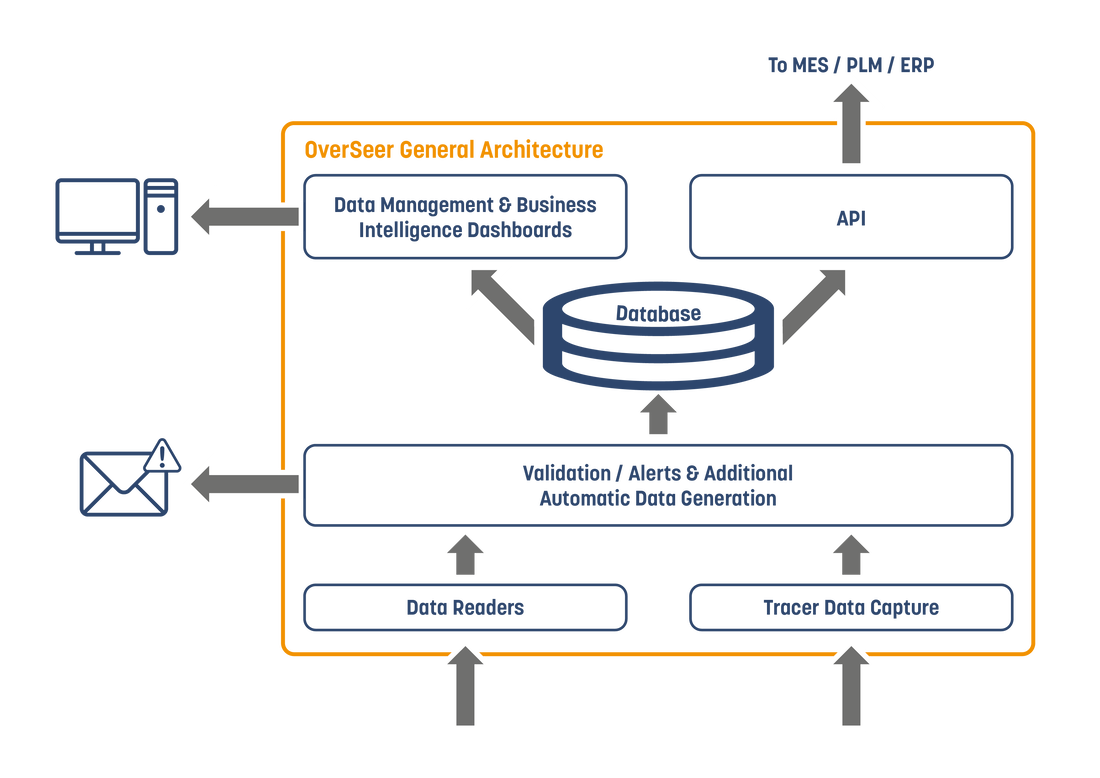

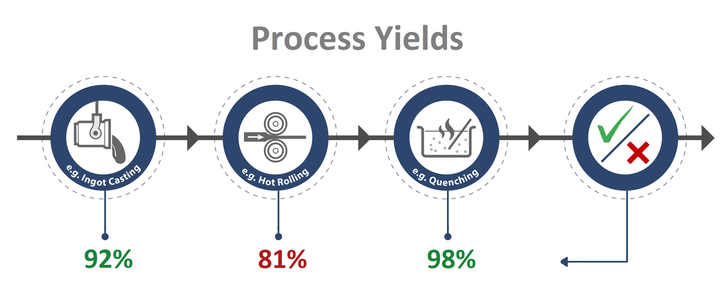

This high-value aerospace manufacturer operates many inspection processes at various stages of manufacture. Their inspection processes were disparate, didn’t scale, lacked connectivity, had poor archiving functionality, and didn’t integrate with their wider systems. This global FTSE100 manufacturer identified that this was becoming unsustainable and was placing a large maintenance overhead on the team. Whilst their existing analysis programs used Excel and Visual Basic, this limited the opportunity for large-scale, real-time, cross-technique data analysis. Following in-depth meetings and discussions with the client to discover exactly what they required, we came to the conclusion that OverSeer and our other associated modules directly solved their problems.

Overcoming Manufacturing Challenges

From the outset, this project introduced some distinct challenges for us, as we were required to retrofit our solutions into existing processes and data outputs. While our systems are designed to be extensible, the quantity and age of some of the data proved to be a large body of work. For example, some of their data had artificial historical dates used to combat the Y2K incompatibility.

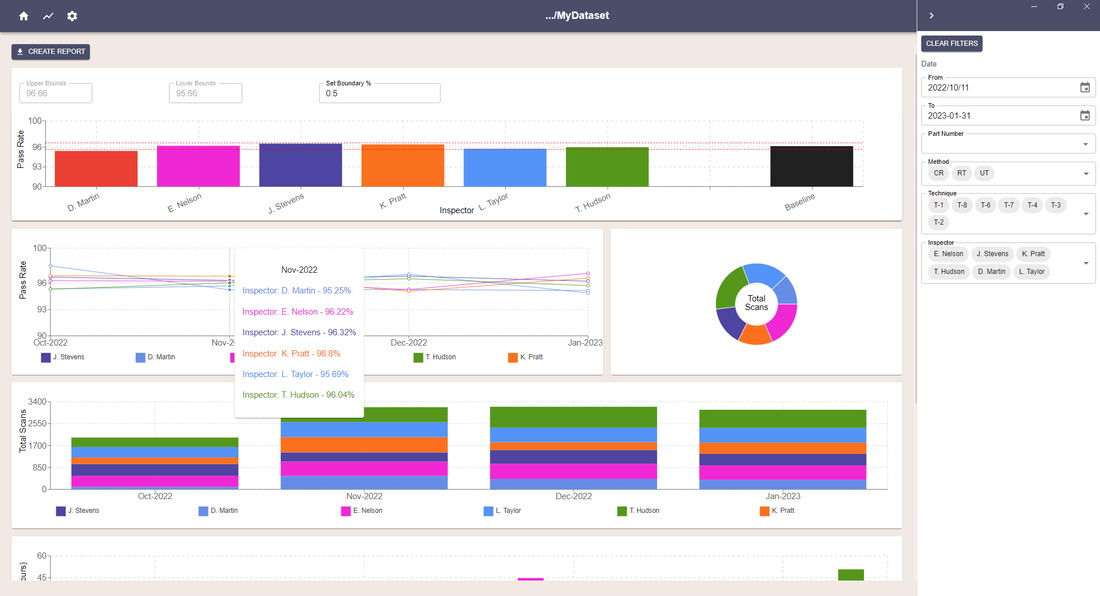

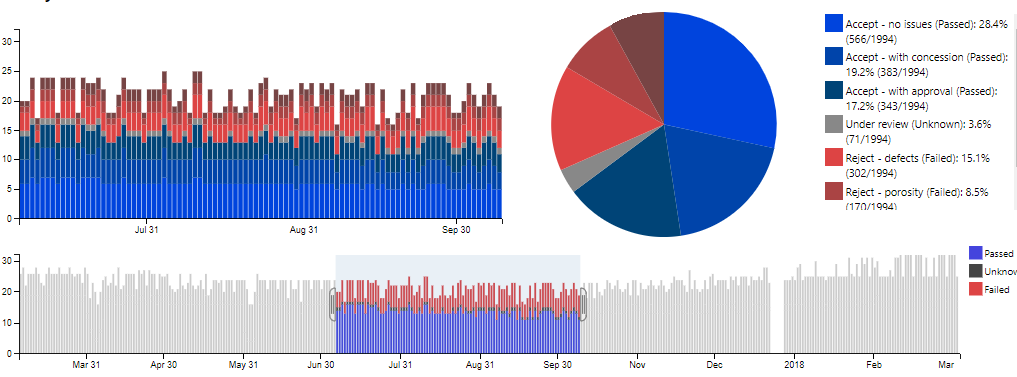

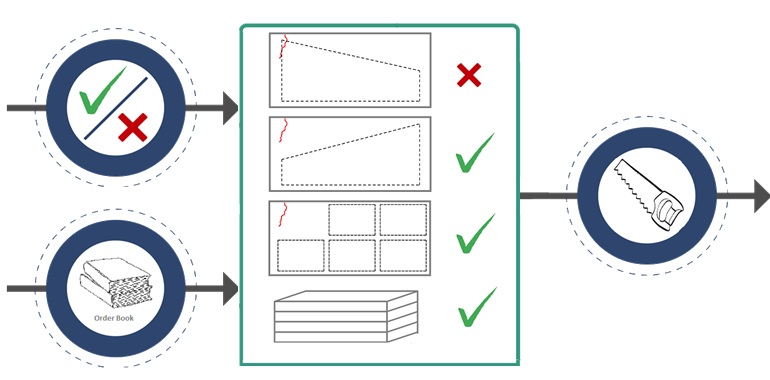

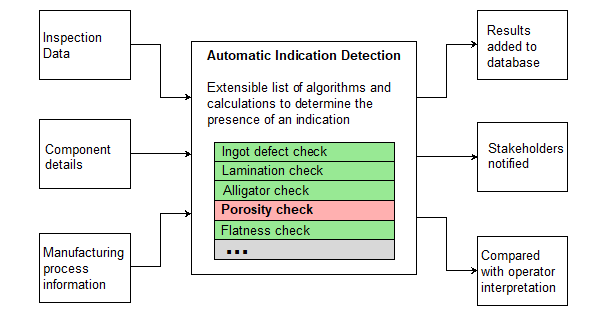

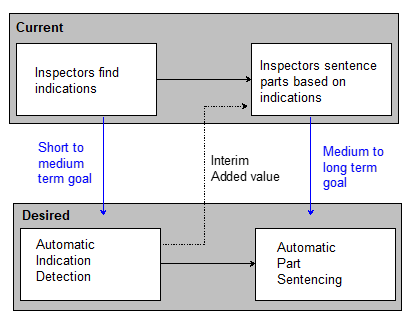

We translated existing VB code and Excel tools into our framework, enabling automatic analysis across a greater data volume and multiple datasets, with stakeholders notified in real-time of results.

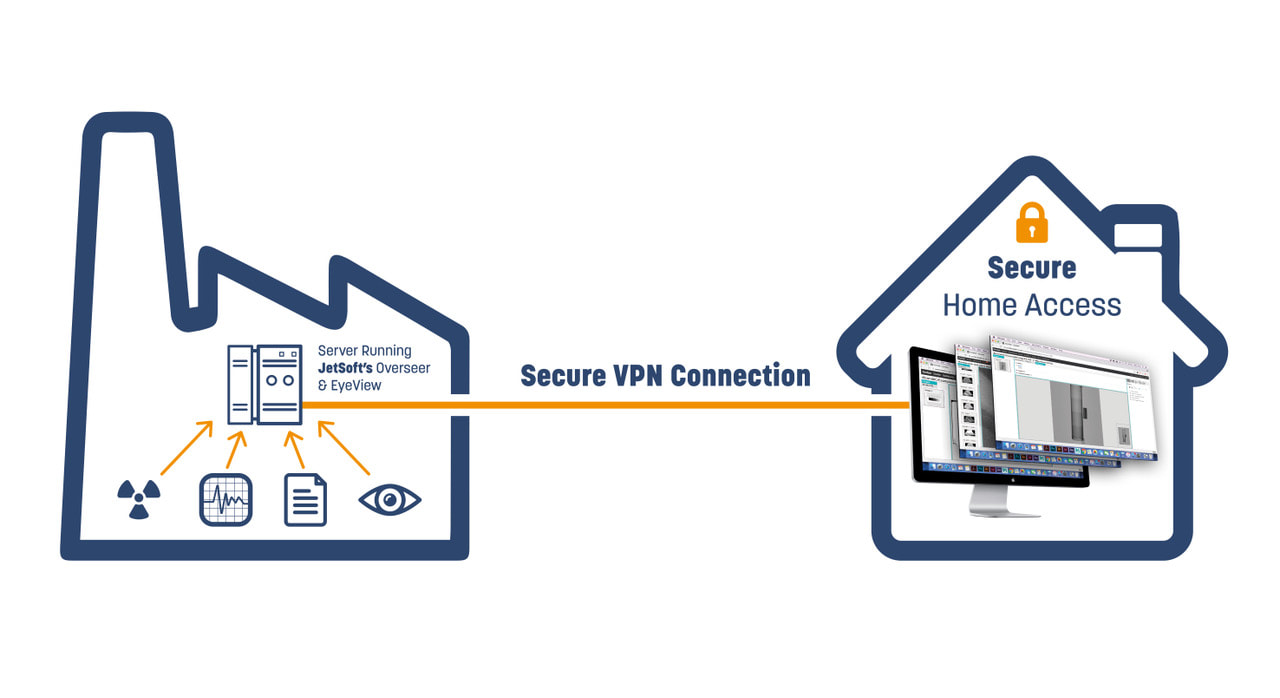

Additionally, OverSeer integrates with the customer's active directory to enable a more streamlined and centrally controlled experience, for a more efficient production line.

A Bespoke Solution

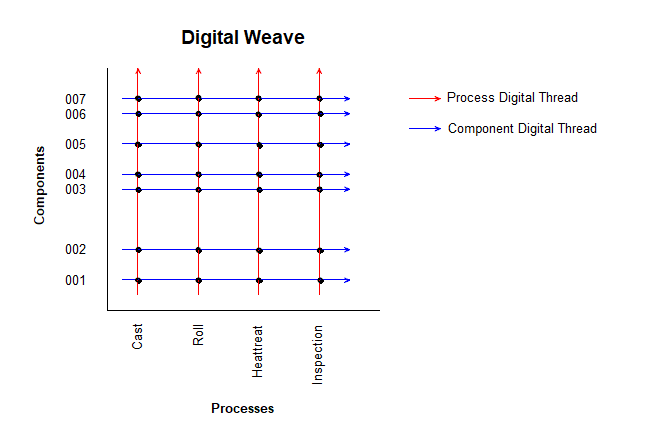

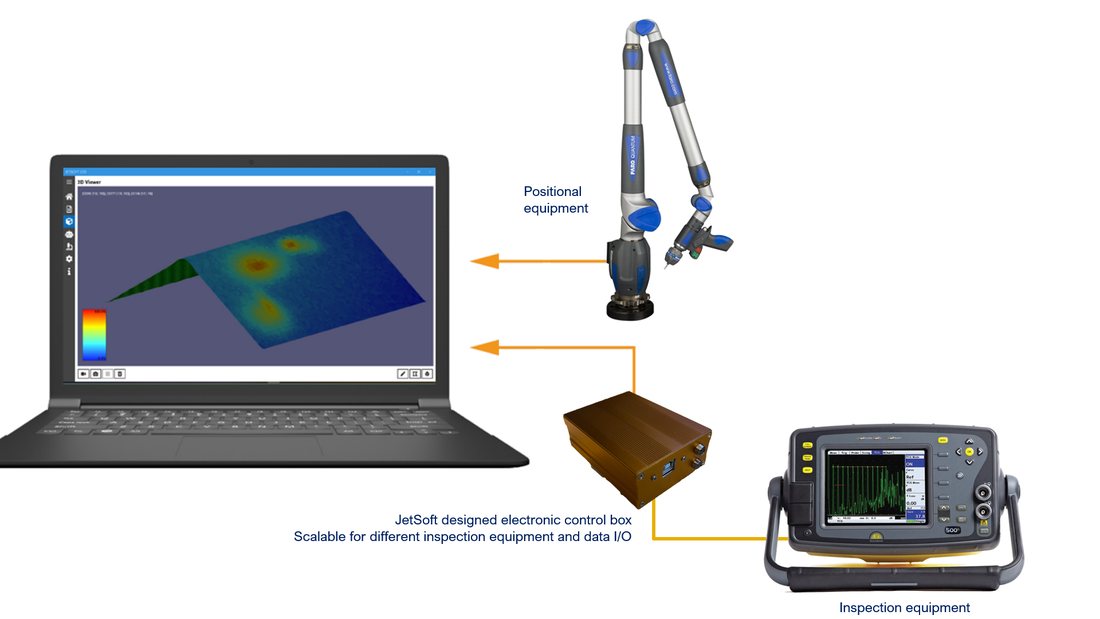

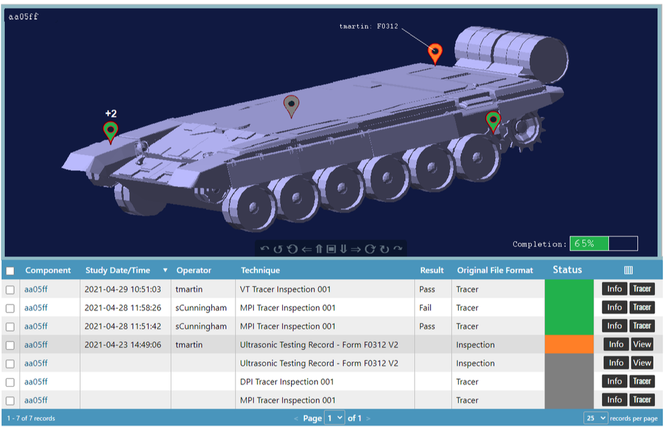

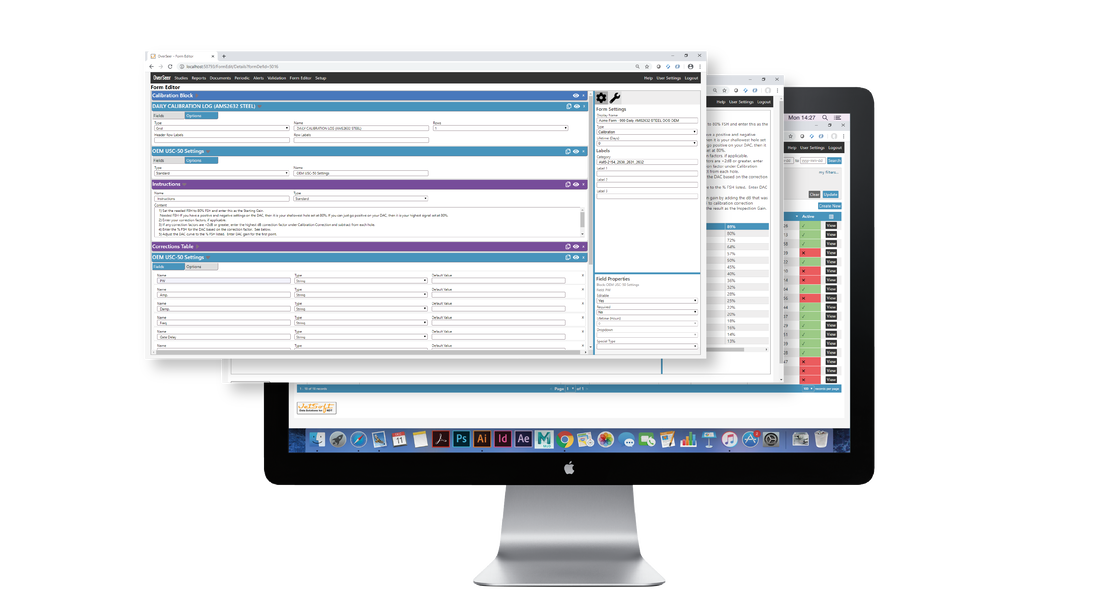

Using our OverSeer solution, we designed a tailored system that delivers maximum benefit, by merging data from ultrasound, digital x-ray and visuals, from formats including TIF, DICONDE, CSV, C-Scan, UT Thickness and JPEG2000, combining this alongside their other manufacturing data. In addition to using OverSeer’s UI tools, we also incorporated several existing analysis programs for inline, in-depth, real-time analysis across inspection datasets. By reading all their data formats and aggregating this into a single solution, we are able to build this into their existing analysis tools. The solution offers many additional advantages to the client, including web-based access, alerts, cross technique data analysis.

Whilst this project is still ongoing for one the largest companies in the UK, the client is extremely happy with the results, being able to regain full control of their NDT data.

If you are looking to produce an efficient production line with tailored technological solutions, get in touch to find out how we can help you.